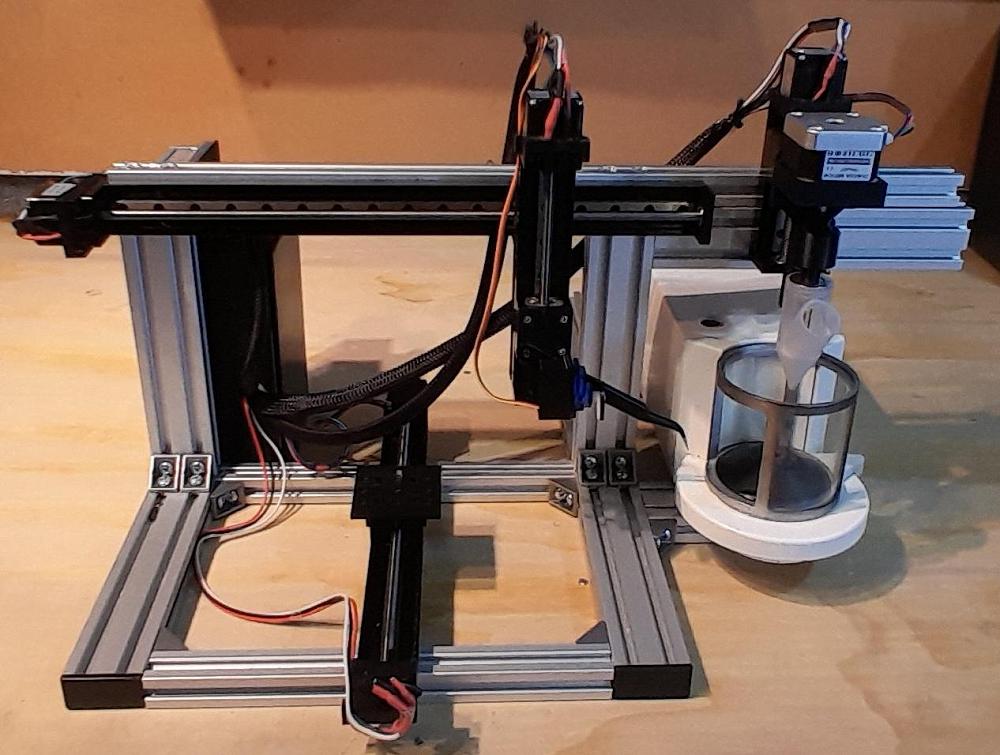

Automated microgram dispenser

A robot dispenser developed by Josh Frew won best project at the Otago Polytechnic Engineering Student Showcase.

The client for this project, Isotrace New Zealand, analyses materials on an atomic level for research, forensic, government and commercial purposes. Isotrace needed to weigh out hundreds of samples a day, a repetitive and time-consuming process. They approached Josh to engineer an automated solution.

This was a complex problem needing a high degree of accuracy. The goal was to dispense samples weighing within 10 percent of 400 micrograms, into cups as small as 3.5mm in diameter. Contaminants such as lubricating oils needed to be kept out of the samples. Josh designed an auger and hopper to be loaded with powder for analysis. The hopper can be filled easily from the side. A stepper motor dispenses the correct amount of powder into the cups, which are placed on a balance to determine the correct weight. The whole process is automated with a robot which moves the cups to the dispensing location, runs the motor until the desired weight is reached, then returns the cups to the rack and fetches a new cup for the next sample. This is all part of the closed-loop system Josh has developed over the last year and a half.

Initial results from the robot dispenser were impressive. After a hundred test runs, the dispenser showed good consistency with 60 percent of samples falling within the correct weight range. With fine tuning, the accuracy improved even further. Josh Frew’s microgram dispenser fulfils the client’s brief to free up staff time by automating a repetitive yet essential process without compromising quality.

Adam Liberatore, Principal Lecturer in Engineering Technologies, says:

A great technical project from an industry partner. Josh iterated through many ideas and designs with the support from a group of helpful staff and technicians. A functioning result for the client as well!